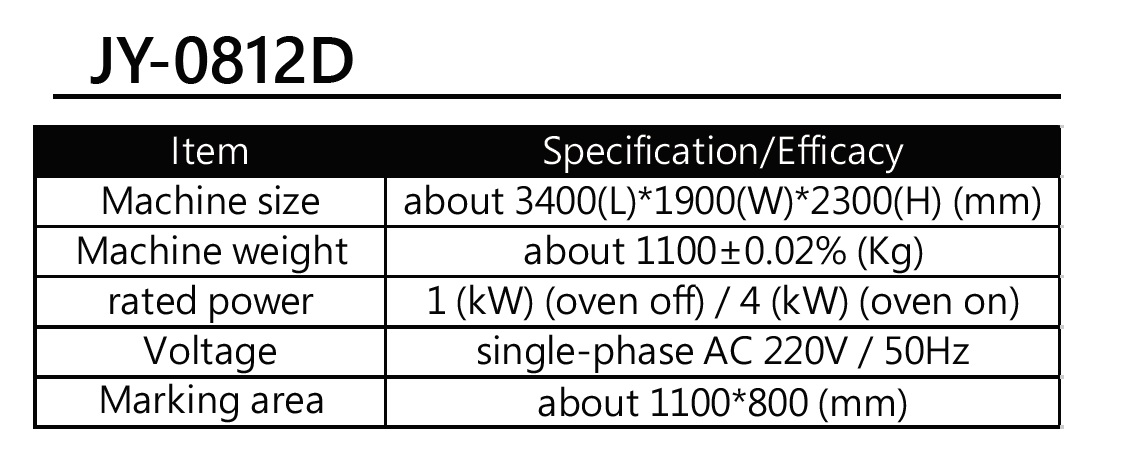

JY-0812D

Machine Features:

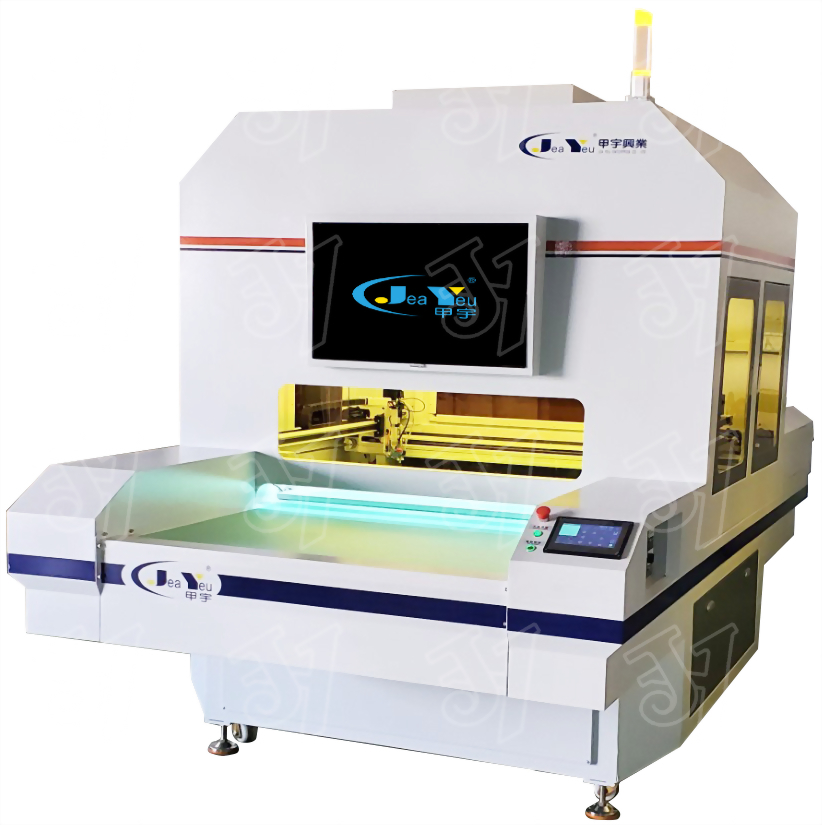

1.The whole machine consists of three workstations: the unloading area, the vision positioning and line drawing area, and the material receiving area;

the vision positioning and line drawing area has a grid pneumatic pressure net that can flatten the workpiece even if the workpiece is warped.

2.Equipped with a high-precision industrial camera and vision positioning software, different types of workpieces can be placed and distinguished;

vision positioning is precise, saving space in the production and storage of stencils and molds.

3.Vision positioning software has the function of deforming and matching workpieces, improving accuracy and production speed. The software operation is simple and easy to learn, reducing the burden on operators and assisting enterprises in automated production.

4.Equipped with pneumatic high-speed injection valve, suitable for various fluorescent inks, disappearing inks and water-based inks.

5.The pneumatic high-speed injection valve adopts XY-table movement method and high-quality servo drive module, which is fast, high-precision and low failure rate.

6.Using a quick-detachable ink supply tube structure, cleaning and maintenance are quick and easy.

7.Equipped with a low-energy-consumption temperature-controlled oven system and UV illumination lamp, which can be used flexibly with different inks and process requirements.

8.Save labor costs, improve production efficiency, reduce consumable costs and eliminate environmental pollution caused by screen printing inks.